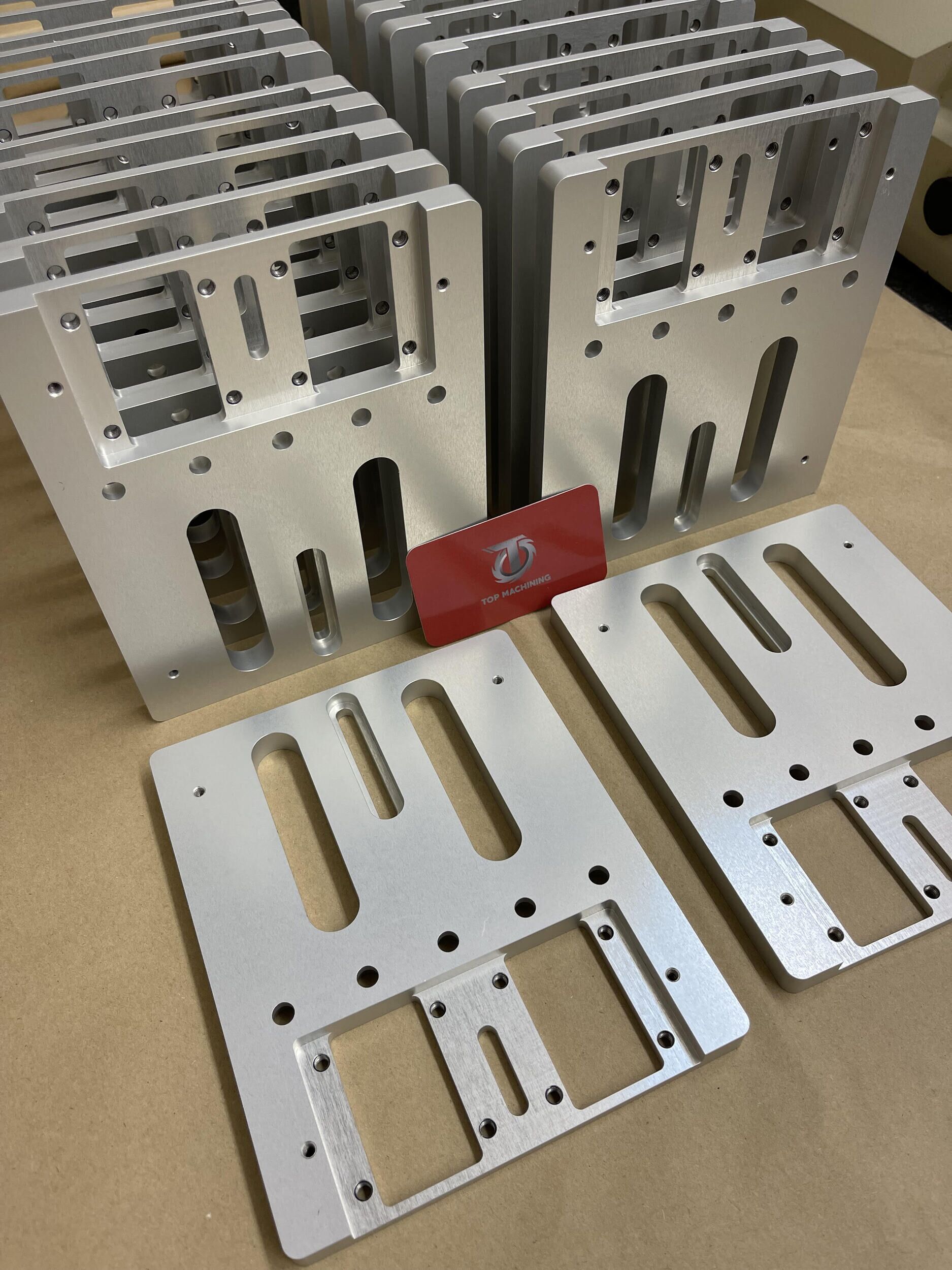

Full-Service Precision Manufacturing from Prototype to Production

At TOP Machining Inc., we combine advanced technology, skilled craftsmanship, and industry-leading quality systems to deliver high-precision machined components — on time and on budget.

From single-part prototypes to full production runs, we handle every stage of your project with accuracy, speed, and reliability.

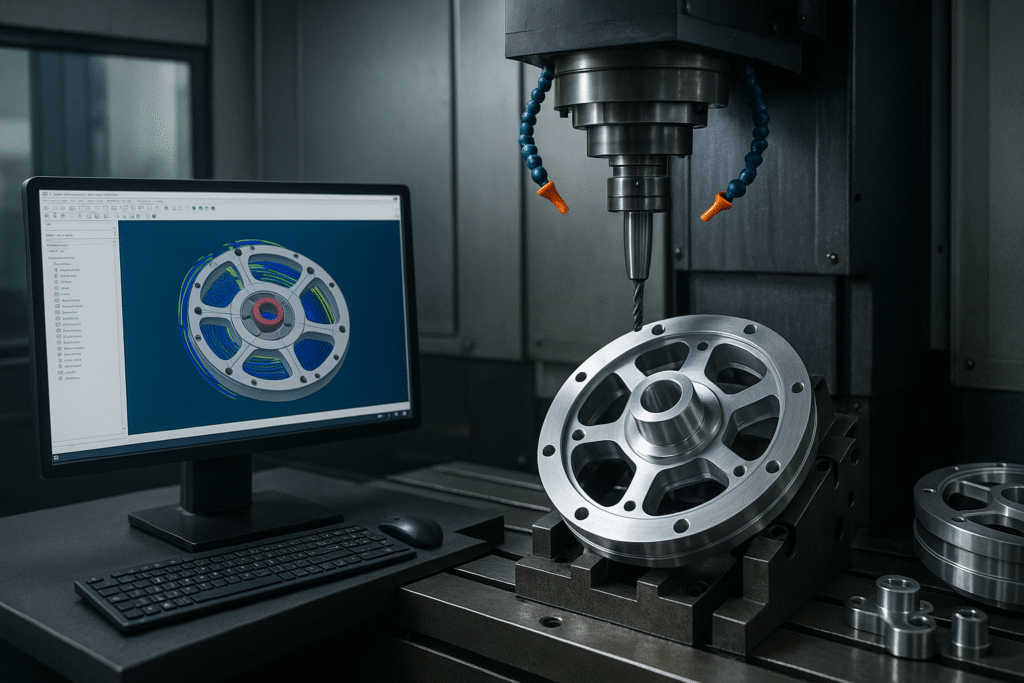

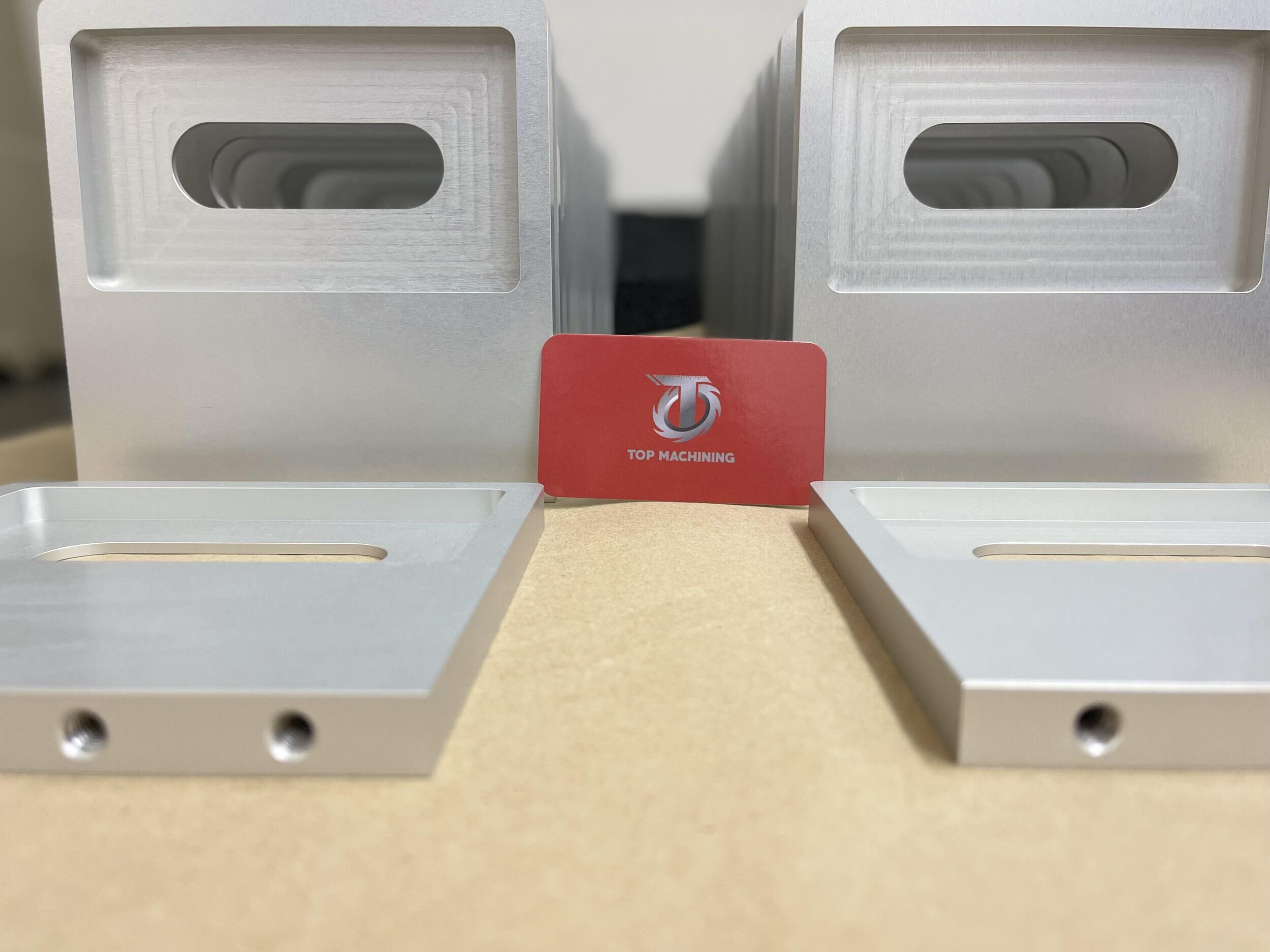

CNC Machining

CNC machining is a specialty of our team here at TOP Machining, and as such, we can offer the following services:

- Manual Mill/Lathe – When necessary, we have the capabilities to offer highly intricate parts to be cut and milled manually.

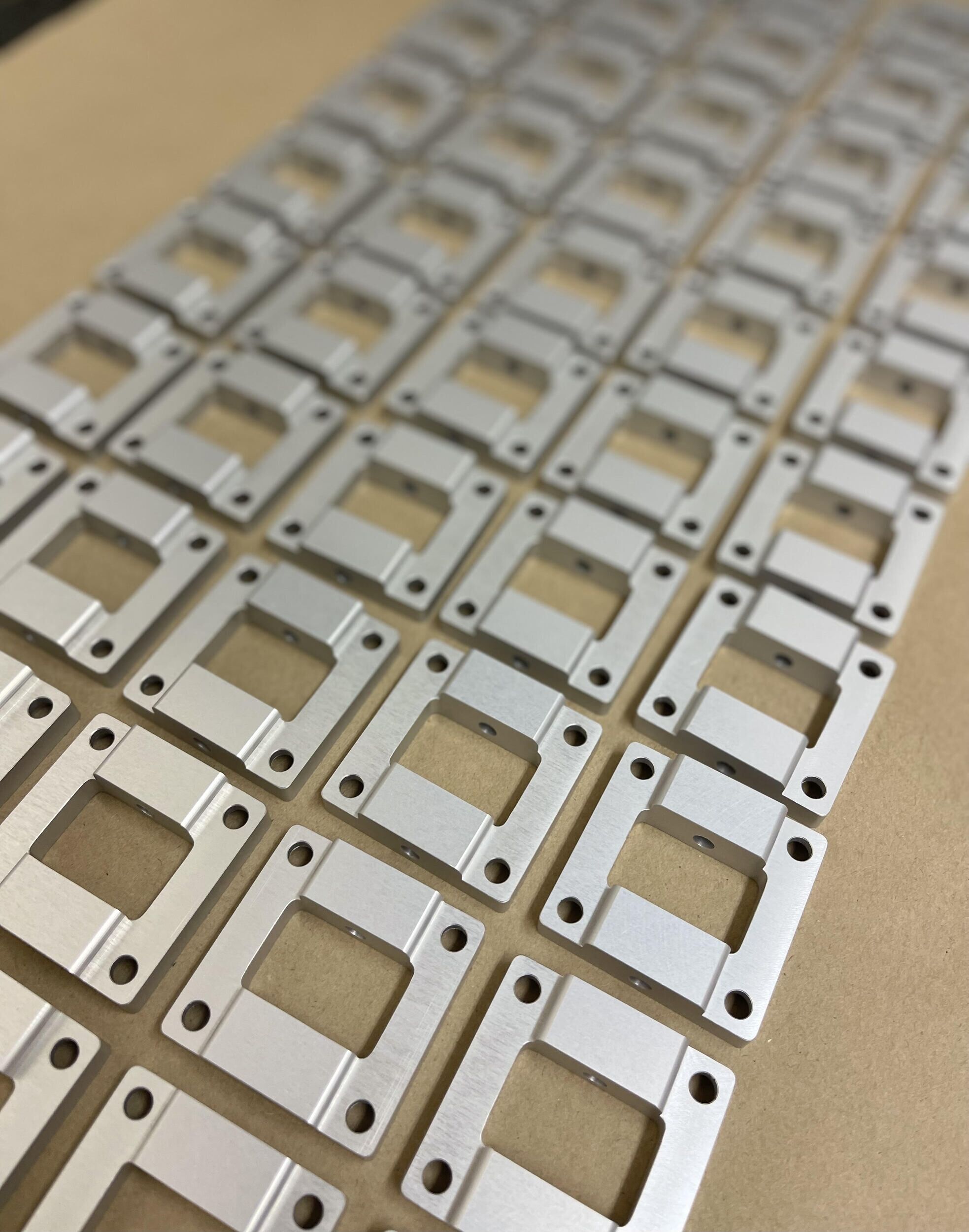

- Multi-axis Milling – Our CNC milling department features state-of-the-art 3-, 4-, and 5-axis machines capable of producing complex geometries with superior surface finishes.

We manufacture everything from small intricate components to large structural parts — ensuring perfect dimensional accuracy and repeatability.

- Turning/Lathe – We specialize in CNC turning for round, cylindrical, and multi-feature parts that demand precision.

With live-tool and sub-spindle capability, our lathes reduce multiple setups into a single operation — improving both quality and cost efficiency.

Programming

Our highly experienced programmers use the latest CAD/CAM software to convert your 3D models into optimized toolpaths that maximize speed and accuracy.

We analyze tolerances, cutting forces and feed rates to produce parts efficiently and right the first time. There is no upper or limit to our capabilities.

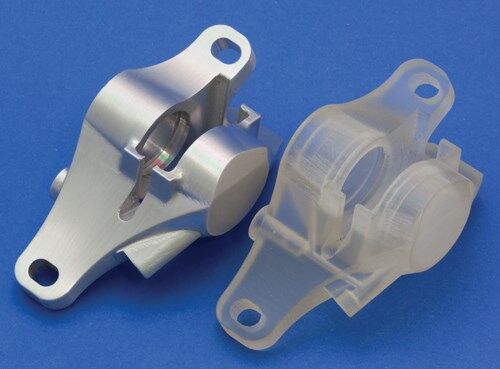

Rapid Prototyping & Short-Run

Bring your ideas to life quickly. Our prototyping service allows engineers and designers to test concepts fast, with a variety of materials including aluminum, stainless steel, titanium, and engineering plastics.

We help you refine designs for manufacturability before scaling up to full production — reducing lead time and waste.

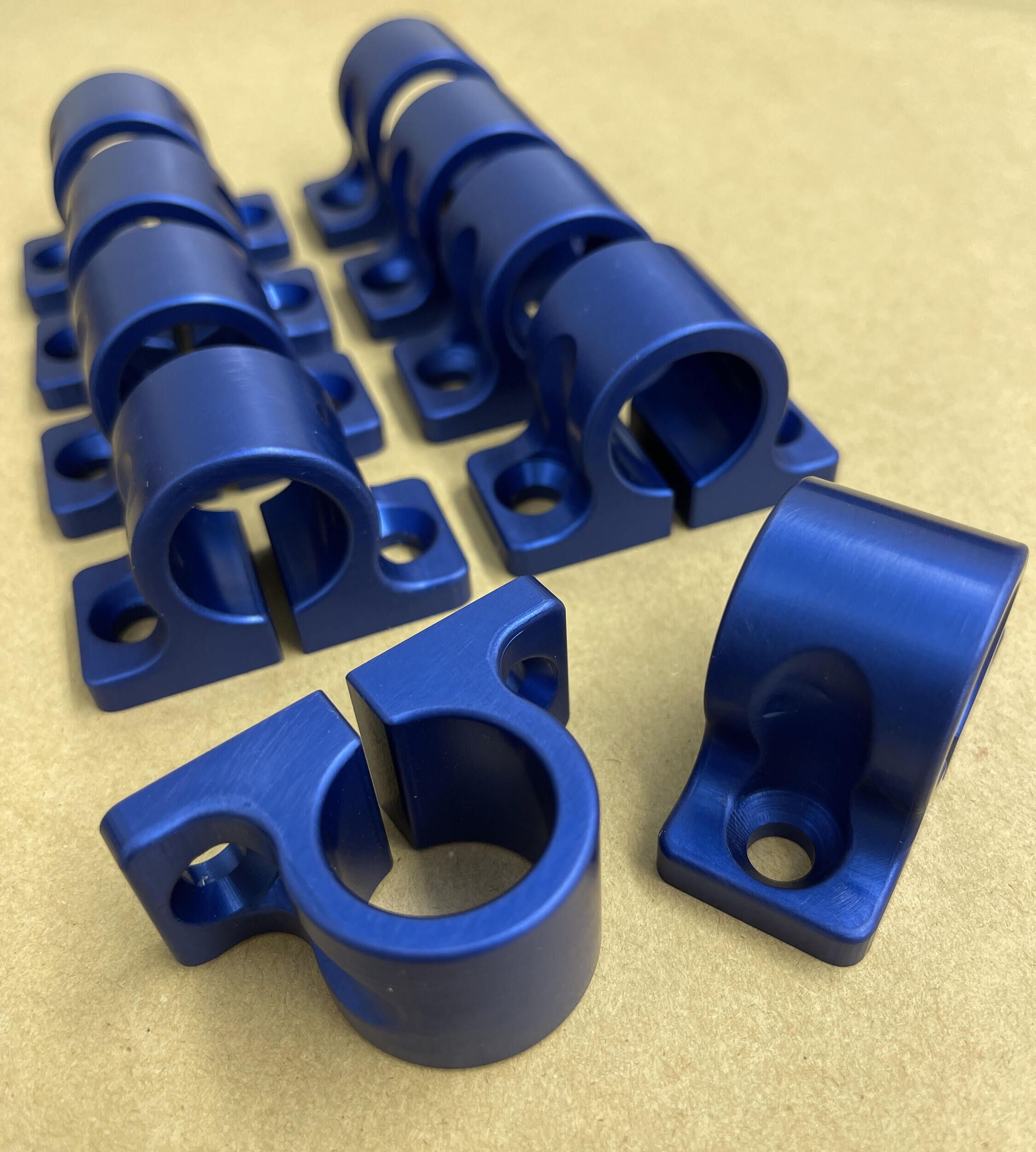

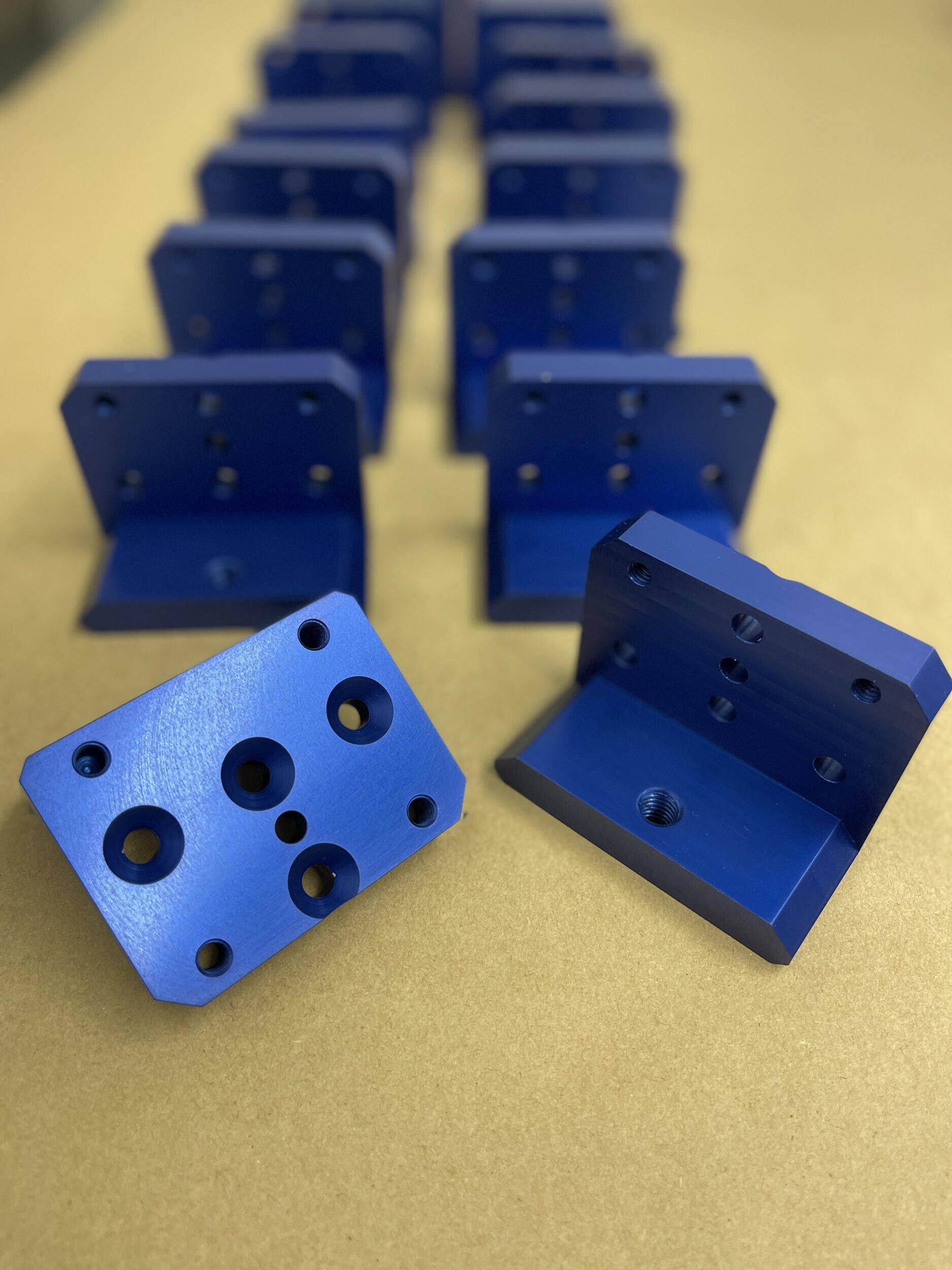

Production

When your design is ready for mass production, TOP Machining Inc. delivers consistent quality at scale. We understand the production manufacturing challenges and can meet your operational demands while keeping the costs to an absolute minimum.

Using lean manufacturing practices and detailed process control, we efficiently manage large-volume orders while maintaining precision and traceability.

Our production capabilities include:

- Multi-axis CNC machining

- Lot-based inspection & documentation

- Dedicated fixturing and process optimization

- Full traceability per ISO 9001 / AS9100 standards

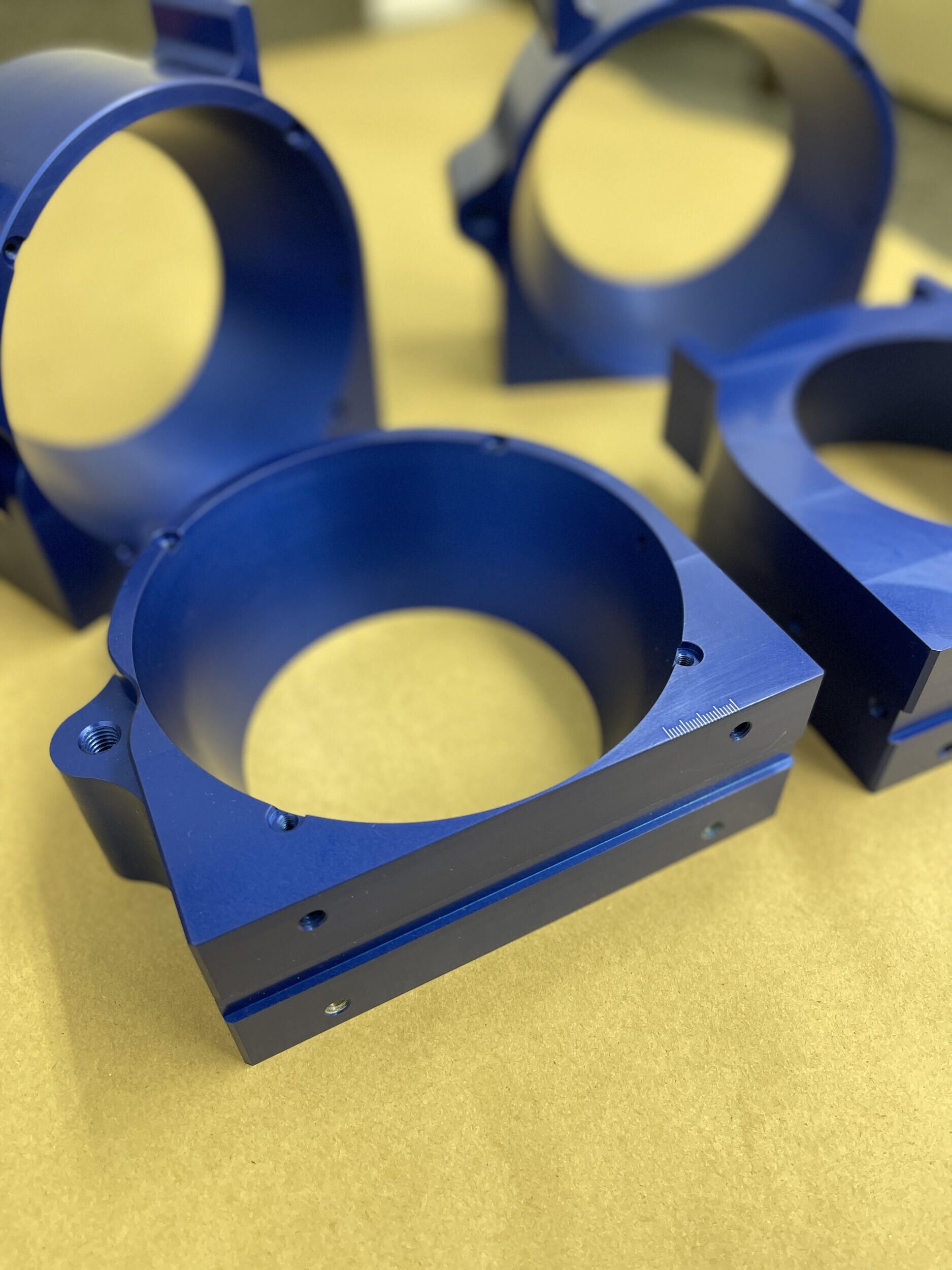

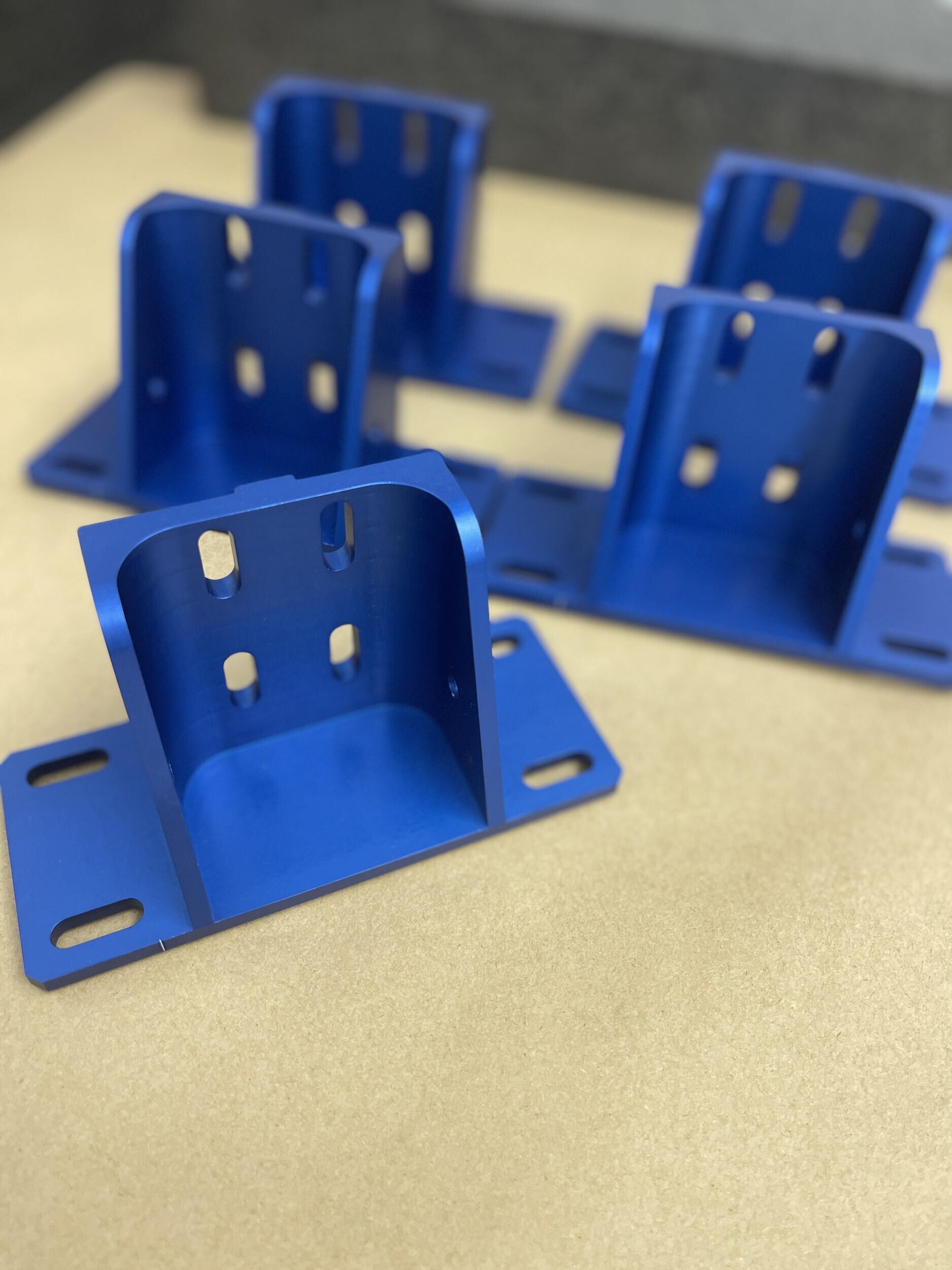

Turnkey Assembly & Finishing Services

We provide turnkey manufacturing solutions — taking your project from raw material to finished assembly.

Our services include:

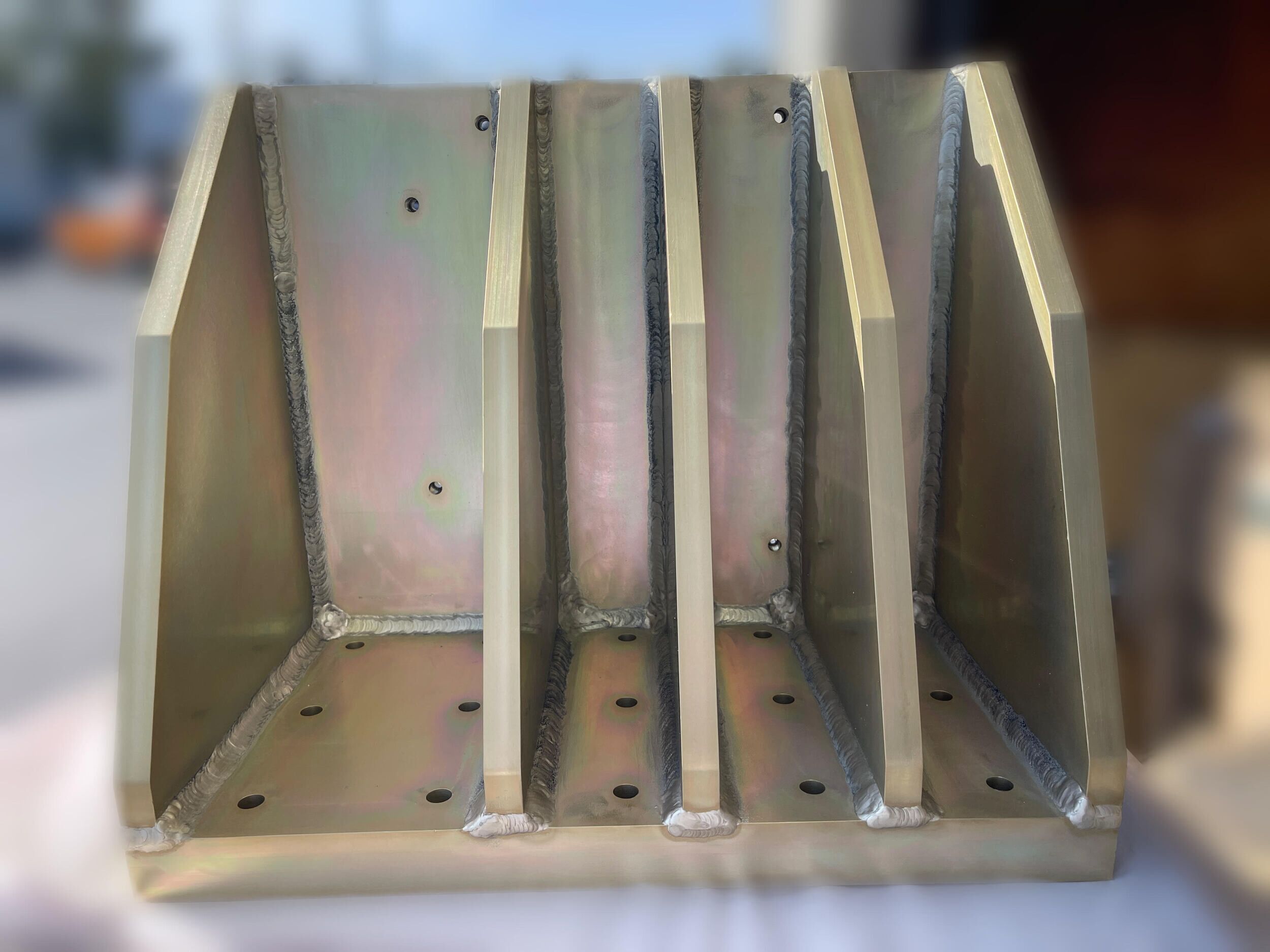

- Laser Machining / Sheet Metal / Welding

- Mechanical assembly

- Bead blasting, anodizing, and plating

- Laser marking and engraving

- Painting and powder coating

- Final inspection and packaging

This means fewer vendors, shorter lead times, and a single point of accountability for quality.

Materials We Machine

We work with a wide range of metals and engineering plastics to meet any requirement:

Metals: Aluminum, Stainless Steel, Titanium, Copper, Bronze, Brass, Tool Steel, etc.

Plastics: Delrin (Acetal), PTFE, PEEK, Ultem, Acrylic, Nylon, Phenolic, G10, F4, Vespel, etc.

Every material is processed according to its unique thermal and mechanical characteristics to ensure optimal strength and finish.